PRODUCT CATEGORIES

NEOS (MODEL 2023)

NEOS: THE EVOLUTION KEEPS GOING

Atlanta Stretch strongly wanted to add Neos to its series of self-propelled wrapping robots. This top-ranked model is the only robot that can be equipped with ARYA a new patented technology that actually makes the wrapping process fully automatic.

Neos marks a breakthrough innovation in the panorama of semi-automatic stretch wrappers as it does not require the intervention of the operator to hook the film to the pallet performing a fully automatic cycle, without using compressed air and without mechanical options susceptible to wear and tear. To discover the patented ARYA system, click here.

Neos comes with a new design that seems to break completely with the past: eye-catching lines give strong character to the new Atlanta Stretch wrapping robot.

NEOS inherits all the expertise of Atlanta Stretch; this model boasts all the features and options of the Sfera series: it includes the possibility to choose between FM, FE, PRS and PS carriages and to replace them even after purchase where the customer’s needs require an upgrade of the machine.

The dual-motor PS pre-stretching carriage allows Neos to guarantee the lowest film consumption and highest functional reliability in the wrapping machine market.

Compared with Sfera Neos series, it has increased battery capacity to 120A, and new operator interface with 7-inch touch screen panel that can be programmed quickly and easily, installed. LEDs indicate the machine’s current status.

Neos, equipped with PS carriage and ARYA system, is the ground-breaking robot the market has been waiting for!

SYNTHESI

SYNTHESI

SYNTHESI is an economical and easy to operate stretch wrapping machine, which can be equipped with three different film carriages FM / FE and OPRS. Enables you to own a POWER PRE- STRETCH machine for an affordable price. This model is highly demanded by those users wrapping limited pallets per day, and still interested to achieve a low cost of ownership. SYNTHESI answers to those needs, already supplied as a full equipped machine, many options are available to be installed, in order to make this machine become your best partner in logistics.

Eva

FIRST STEP, ECONOMIC, SIMPLE, RELIABLE CHOICE

Machine is supplied with one basic program and has limited wrapping options. It comes with a mechanical brake type film carriage system. Entry level turntable wrapper, suitable for wrapping a low number of pallets per day (<15 Pallets)

libra easy

STOP THE PALLET ROTATING

Compact, rotating arm machine to wrap pallets with pre-stretched film. Small footprint, reduced operating costs.

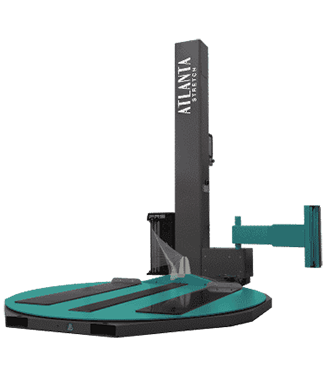

SFERA WITH MAST

LIMITLESS WRAPPING SOLUTIONS

Starting as a low-cost model the SFERA mobile wrapping machine can grow with the needs of your business. Providing real value for money, it is guaranteed to be the best value packaging machine equipped with a pre-stretch film system.

If you decide to buy the model with FM carriage this can easily be upgraded to our power pre-stretch system, which can be supplied with either ONE or TWO Motors depending on your requirements.

The easy to use 11″ TOUCH SCREEN operating panel allows you to setup a number of different parameters, these ensure the best quality wrapping patterns. Our enhanced version PLC provides up to 99 programs suitable for every kind of wrapping pattern for differing and varied products. This machine is ready for pallet wrapping in the 21st century.

MYTHO S

Mytho S: your operators will love you boss!

MYTHO S was born from the desire of Atlanta Stretch to add a top of the line to its semi-automatic turntable pallet wrapping machines.

The new casings on the mast and motor that make this new model look like a design machine actually conceal a mast with reinforced guides. LEDs indicate the machine’s current status.

The main feature for Mytho S consists in being the only turntable wrapper that can be equipped with the ARYA system; a new patented technology that makes the wrapping process fully automatic.

Mytho S marks a breakthrough innovation in the panorama of semi-automatic stretch wrappers as it does not require the intervention of the operator to hook the film to the pallet performing a fully automatic cycle, without using compressed air and without mechanical options susceptible to wear and tear. To discover the patented ARYA system, click here.

All Atlanta Stretch options for the table are available also for Mytho S: possibility to choose from FM, FE, PRS and PS carriages and replace them even after purchase if the customer’s needs change with business growth.

With the dual-motor PS pre-stretch carriage, Mytho S can guarantee the lowest film consumption and highest functional reliability in the wrapping machine market.

The Mytho S, equipped with PS carriage and ARYA system, is the most cutting-edge semi-automatic wrapping machine on the market.

MARATHON

YOUR WORKERS ARE THE WRAPPING MOTOR

- Marathon stands out for its simplified functions and ability to use pre-stretched film.

- A wrapping machine for palletised loads of any shape, weight and size.

- The world’s unique non-electric robot that can wrap pallets with LLDPE pre-stretched film.

- Marathon replaces manual wrapping, at an affordable price.

- Easy and smooth manual movement of the machine, obtained without an electric motor.

- The spool carriage is manually moved up and down to suit the required wrapping.

SYNTHESI WITH ARM

THE MOST FLEXIBLE SOLUTION FOR YOUR GROWING BUSINESS

Starting as a low-cost model the SYNTHESI can grow with the needs of your business. Providing real value for money, it is guaranteed to be the best value packaging machine equipped with a pre-stretch film system.

If you decide to buy the model with FM carriage this can easily be upgraded to our power pre-stretch system, which can be supplied with either ONE or TWO Motors depending on your requirements.

The easy to use 11″ TOUCH SCREEN operating panel allows you to setup a number of different parameters, these ensure the best quality wrapping patterns. Our enhanced version PLC provides up to 99 programs suitable for every kind of wrapping pattern for differing and varied products. This machine is ready for pallet wrapping in the 21st century.

MYTHO AUTO WITH MAST

YOUR WORKERS CAN DO MORE IMPORTANT THINGS!

The MYTHO Auto simplifies the automated pallet wrapping process. It reduces costs without any reduction in quality or speed. Operators load pallets onto the turntable and start the machine. From that point on, the process of wrapping the pallet is fully automated. This includes the film tail being cut and the option of welding the tail against the pallet. Operators then finish the process by unloading the wrapped pallet from the turntable.

The easy to use 11″ TOUCH SCREEN operating panel allows you to setup a number of different parameters, these ensure the best quality wrapping patterns. Our enhanced version PLC provides up to 99 programs suitable for every kind of wrapping pattern for differing and varied products. This machine is ready for pallet wrapping in the 21st century.

SFERA WITH ARM

LIMITLESS WRAPPING SOLUTIONS

Starting as a low-cost model the SFERA mobile wrapping machine can grow with the needs of your business. Providing real value for money, it is guaranteed to be the best value packaging machine equipped with a pre-stretch film system.

If you decide to buy the model with FM carriage this can easily be upgraded to our power pre-stretch system, which can be supplied with either ONE or TWO Motors depending on your requirements.

The easy to use 11″ TOUCH SCREEN operating panel allows you to setup a number of different parameters, these ensure the best quality wrapping patterns. Our enhanced version PLC provides up to 99 programs suitable for every kind of wrapping pattern for differing and varied products. This machine is ready for pallet wrapping in the 21st century.

LYBRA

INSTABLE PALLETS, VERY STABLE LOW FILM CONSUMPTION

Compact, high performance rotating arm machine for wrapping pallets with stretch film. Reliable, robust construction.

LYBRA S

INSTABLE PALLETS, VERY STABLE LOW FILM CONSUMPTION

Compact, high performance rotating arm machine for wrapping pallets with stretch film. Reliable, robust construction.

LYBRA AUTO

Automatic rotating arm stretch wrapper

Compact, high performance rotating arm machine for wrapping pallets with stretch film. Reliable, robust construction. Equipped with electrical distributor and gears system for rotation of the arm. Standard delivery with FE Magnetical brake system.

Easy to use, 99 pre-set wrapping cycles and the possibility of programming an unlimited number of options. Electronically controlled pre-stretch carriage with rapid film loading system. (IRF SYSTEM).

SEMI AUTOMATICS ROTATING ARM MACHINES

ECOWRAP is a semi-automatic machine with rotating arm ideal for wrapping with stretch film products particularly unstable, the chance ‘to keep the pallet stop and stabilize the product by turning a rotating arm. This machine is the right solution for environments logistics.

SEMI AUTOMATICS ROBOT MACHINES

The new ROBOT , wrapping machines, positions Atlanta as the best partner for all manufacturers who require maximum warehouse logistics and management. Robot demonstrates its leadership due to the new technical innovation for simplifying its use. ROBOT is designed and produced according to the policies that distinguish Atlanta in terms of reliability and durability. Every single detail was designed selecting the best materials on the market. No detail was left behind and the hi-tech solutions and craftsmanship can be seen in each inch of the machine.

FULLY AUTOMATICS ROTATING ARM

Automatic entry level rotating arm stretch wrapping machine that takes advantage of the know-how acquired over 25 years of leadership in stretch wrapping. The new machine offers continuity solutions with the wrappers of previous generations, and adds innovative solutions to best meet the needs of the customers.

The standard pre-stretch carriage model PGSM, with the adoption of optional kits, allows fixed ratio up to 300%, while the optional double motor pre-stretch carriage model PGSA allows adjustable force to load and prestretch up to 350% from control panel. Both the carriages can be equipped with 750 mm (30”) film reel height.

FULLY AUTOMATICS RING

A wide range of rotating ring stretch wrapping machines to wrap and stabilise loads on pallets with stretch film suitable for all industry sectors.

The Genesis Futura series of pallet stretch wrapping machines operate without sliding electrical contacts and feature the exclusive system that powers the pre-stretch driven rollers using batteries which are charged during machine pauses at pallet infeed and outfeed. This technical and highly innovative solution, in addition to eliminating all the typical problems of sliding contacts, also significantly reduces the overall machine weight and correctly balances the rotating masses.

This results in low electrical energy consumption, reduced maintenance, high reliability and long working life.

Furthermore, construction solutions have been adopted to minimise transport costs and installation time giving economic advantages for the end user.

Maximum output capacity 65 Pallet/h depending on line speed and the total number of revolutions of film required.

Tag : Stretch Wrapping Machine Distributors, Stretch Packing Machine Distributors, Stretch Wrap Machine Distributor, Pallet Stretch Wrapping Machine Distributor, Shrink Chamber Machine Distributor, Robot Stretch Wrapping Machine, Stretch Film Machine Distributor, Stretch Film Wrapping Machine